SL 400

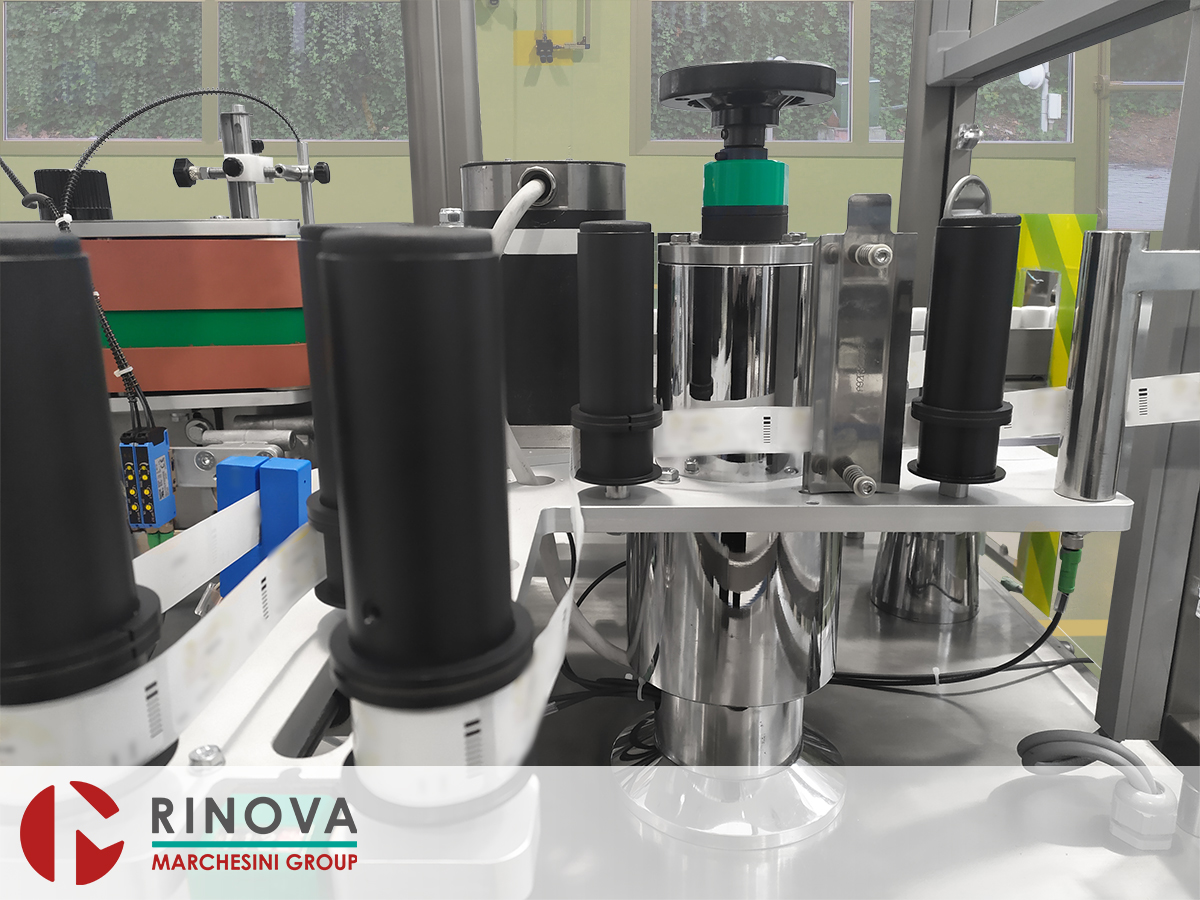

SL 400 Automatic linear self-adhesive labeller

The Marchesini Neri SL 400 is suitable to apply label at high speed on vials, bottles or similar round containers.

Basic machine, stainless steel finish, complying with GMP regulation. Operating in line with other machines or, as a stand-alone equipped with appropriate feeding / collecting systems.

Standard Equipment

- Horizontal conveyor belts with adjustable side guides for handling different bottle sizes;

- Minimum load control at the in feed with machine stop and automatic start;

- Scroll spacing device of containers to handle;

- Gap Control between bottles, if too close immediate machine stop;

- Automatic label change system. Configuration and memorization of different label sizes;

- Label dispensing with stepping motor drive;

- Automatic label unwinder from reel, motor driver and adjustable loop. Photocell providing end of reel control with machine stop;

- Stepping feeding of labels allowing for empty spaces on reel;

- Missing label control on reel;

- Vertical and horizontal adjustment of the label position by means of hand wheel control, complete with digital settings;

- Label smoothing system on vials or bottles with a “mousse” rubber belt;

- Backing paper-rewinding unit, complete with mechanical clutch;

- Work hour counter;

- Bottle rejection system with collection bin.

Machine complete with

- SIEMENS PLC machine management with fail-safe logic;

- Standard operator terminal TP700 Touch Screen;

- Self-diagnostic color 5.7″ video;

- Electric cabinet on board;

- Power at 400 Volt, 3 phases, 50 Hertz, Ground & Neutral wiring;

- Safety Guards with anodized aluminum frame and doors in Methacrylate, with SCHMERSAL safety switches. Machine stop in case a door opens. The machine has all safeties required for a safe operation and corresponds to norms. Machine delivered with CE mark;

- Green color light source warning beacon;

- Compressed air control pressure-switch with machine stop at low-level detection;

- Set of change parts consisting of spacing scroll for One size of bottle.

Technical data

Size range (The indicated data are for reference only. They are subject to be modified whenever manufacturing needs dictate so)

- Reference height (labels): from 10 up to 120 mm

- Reference length (labels): from 13 up to 190 mm

Label production speed

- from 0 to 50 Meters/Minute

Reel diameter

- Max. 400 mm

Reel Core diameter

- 45 or 75 mm

Maximum cadence (pcs/1')

- 400

Standard voltage

- 400 Volts, 3-phase, Neutral & Ground. Frequency: 50 Hertz.

Electrical system

- The machine complies with international CE standards and is tested according certified Quality Plan

Electric cabinet

- Placed on the rear side of the machine, opens completely for easy accessibility

Three colours Advisory Lights (5 functions)

Electric functions

- SIEMENS PLC Serie 7 - 1500

PC Control Panel SIEMENS "TP700"

- Start, stop, reset and emergency push buttons

- Password protected services access

- Touch screen display to visualize advisory messages to the operator

- Function and machine status information

- Production data: partial hours counter with reset, total hours counter, good products counter, speed indicator

- Message presentation including services and Help menu

- Two additional foreign languages can be added to Italian language

- Conforming to EMC norms (El. Magnetic Compatibility)

Installed power

- 2,5 kW

Air consumption

- 7 Bar

Pneumatics components

- SMC

Dimensions

- Approx. Length 2500 mm, Width 940 mm, Height 1880 mm

Net weight

- Approx. 450 Kg

Technical documentation

- Original standard CE Instructions Manual (one hardcopy + one CD Rom) and CE Certificate are supplied with the machine

Commercial References

Gianluca Cavalli - Mirko Malatrasi Sales Managers

Ph. +39 349 392 0666 | +39 342 127 8487

Direct ph. +39 051 0116 303 | +39 051 0116 307

E-mail [email protected]

Ugo Bartolomei Sales & Business Development Manager

Ph. +39 342 778 6619

Direct ph. +39 051 0116 333

E-mail [email protected]